When selecting materials for any project, the choice between acrylic and polycarbonate sheets can make a significant difference in the outcome. Both materials offer unique benefits, but understanding their distinct properties is key to making the right decision for your specific needs. If you are also wondering whether you should go for acrylic or polycarbonate sheets in Canada, then here’s where you will get a clear idea!

So, let’s delve into their specific characteristics. These factors are vital in determining how well the material will perform under stress and in various environments. The first and perhaps most critical aspect to consider is durability and impact resistance.

Durability and Impact Resistance

Polycarbonate sheets are celebrated for their incredible impact resistance. Typically, they are 250 times more resistant to impact than glass and 30 times more than acrylic. This makes polycarbonate an ideal choice for applications where safety and durability are paramount.

- Applications: Protective gear, bulletproof glass, and outdoor structures.

- Benefits: High resilience makes it perfect for high-impact environments.

Acrylic, while not as robust as polycarbonate, still offers good impact resistance and is significantly better than glass. Its advantage lies in its aesthetic qualities and clarity.

- Applications: Signage, display cases, and light fixtures.

- Benefits: Offers a crystal-clear appearance and is more scratch-resistant than polycarbonate.

Light Transmission and Clarity

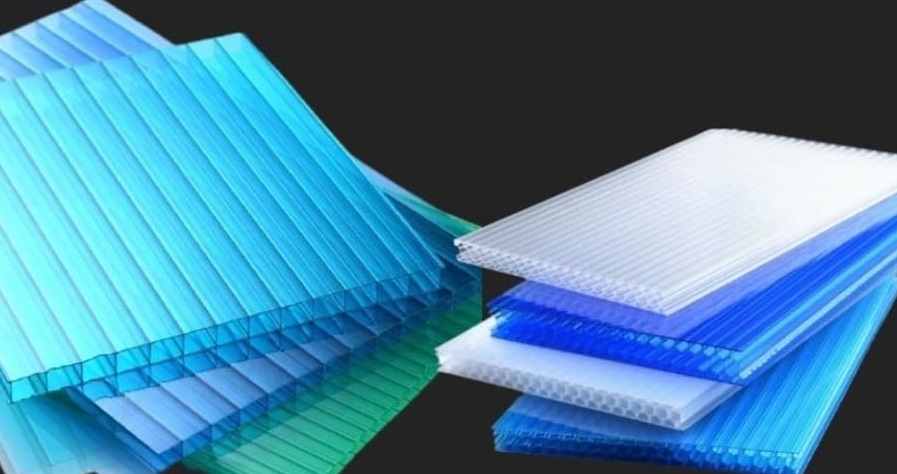

Acrylic sheets excel in clarity and light transmission, with a transparency rate of 92%, making them extremely clear. This property of acrylic sheets makes them a good buy when the users want a glass-like appearance. Polycarbonate, while slightly less clear than acrylic, still provides excellent light transmission and is often used in situations where light must pass through a durable material. For instance, polycarbonate sheets are good to be used for skylights and as numerous other protective barriers.

Machinability and Workability

Given their strength, working with polycarbonate plastic sheets is remarkably flexible. They can be drilled, cut, and shaped more easily than acrylic without cracking or breaking, which is a significant advantage in industrial applications. Polycarbonate tube cutting and shaping are also easier due to the material’s ductility. On the other hand, acrylic sheets offer their own benefits in terms of workability. They can be cut and shaped precisely, which is excellent for detailed work and fine crafting. However, they are more prone to chipping and cracking during the process.

Temperature Resistance and Weatherability

Polycarbonate’s ability to withstand extreme temperatures and resist UV damage makes it suitable for outdoor applications. It does not yellow over time and maintains its strength in varying weather conditions. Acrylic, though it offers good UV resistance and better resistance to scratching, can become brittle in extreme cold. It is best suited for indoor applications or in environments where temperature fluctuations are minimal.

Cost Considerations

Polycarbonate is generally more expensive than acrylic due to its superior durability and longevity. However, depending on the application’s requirements for strength and resistance to elements, the investment might be justified. Acrylic offers a more cost-effective solution for projects where budget constraints are tight and the environmental and physical stresses are lower.

Why Choose Johnston Industrial Plastics?

Johnston Industrial Plastics carries a comprehensive range of polycarbonate tubes, polycarbonate plastic sheets, acrylic sheets, rods, tubes, and an array of other quality plastic materials tailored to your requirements. Whether you need materials for a high-impact industrial application, a high-clarity display, or any other application, we have the inventory and knowledge to support your project.

Explore our vast selection and experience why Johnston Industrial Plastics Limited is among the trusted leaders in Canada for polycarbonate, acrylic, and other plastic solutions. For more information or to discuss your project needs, don’t hesitate to contact us today. Let us help you make the right material choice to ensure the success of your applications.